| FENSYS PRODUCTS are strong, durable and made to last; they are manufactured using recycled material and are 100% recyclable. Balustrade skirting and Premium deck board products are produced with a high grade thermoplastic cap layer onto a commercial grade partly recycled base. The cap layer provides excellent weatherability whilst the base layer delivers a greener foot print; Up to 80% of the base material is of a recycled source and all 100% polymer and 100% polymer composite products are 100% recyclable.

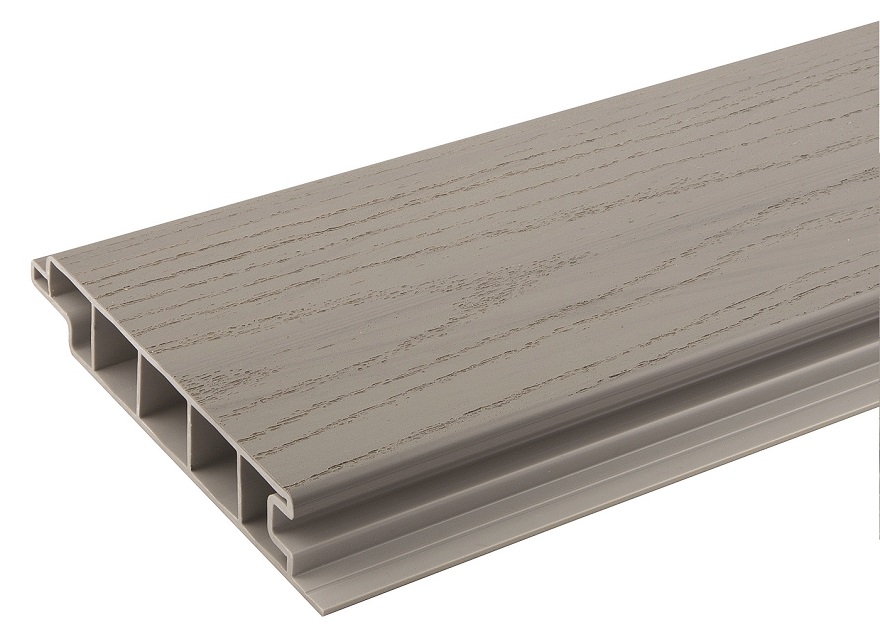

PREMIUM EXCEL & ECO 100% POLYMER COMPOSITE DECKBOARDS are manufactured using the very best outdoor grade materials. By combining a UPVC base layer with a high performance polymer cap layer the boards offer exceptional weatherability. The two polymers types are bonded at melting point yielding a robust composite structure. Excel boards are manufactured using multi colour processing technology resulting in natural effect streaks, tone and colour variation. This means no two boards are manufactured the same and thus provides an unparalleled natural appearance. Dual wood grain patterning further enhances the look and ensures excellent slip resistance . Completing the range our Premium Eco deckboard uses the same cap layer and wood patterning technology but are manufactured from modern single colours. FOILED WOOD GRAIN effect balustrade & skirting finishes such as green, grey, rustic oak and golden oak are all produced using the same type of outdoor grade technical plastic film as double glazed window frames. The film is wrapped onto a partly recycled base polymer resulting in a product that is extremely durable and is 100% recyclable. More product information can be viewed by downloading our literature. FENSYS WOOD PLASTIC COMPOSITE ***product discontinued May 2021***. Manufactured using a 60% wood 40% polymer mix. Boards can be fitted either way up using Fensys nylon fixing clips and suitable screws. Composite materials whilst being more resistant than timber to rot will on exposure to sunlight loose some colour, after 6 months a more natural looking lighter tone of the original colour should be expected, please see the composite gallery for images demonstrating. The boards are strong and robust but thermal expansion and contraction should be considered, a suitably strong sub-frame should be used with maximum joist centres of 400mm, fixing clips are designed to allow expansion and contraction and should be loosely fixed so as not to impair this movement, clearance at board ends is essential with a minimum of 5mm at both ends required. Thermal expansion followed by reversion can lead to boards shirking over the first few months, allow for +/- 2mm movement per metre, cutting and fitting shorter lengths up to 2440mm is recommended to avoid the excessive gaping of longer lengths. Composite trimming angles require the same end clearance and drill over sized holes before loose fixing. Composite materials can and will crack if they are not able to expand. QUALITY STANDARD. All polymer products are manufactured by PAL GROUP (operations) LIMITED under the controls of BS EN ISO 9001 quality standard. A copy of our ISO 9001 accreditation certificate is available on request. WARRANTY. Fensys 100% polymer products are covered by a 10 year limited warranty. Composite materials are covered by our 2 year limited warranty. Copies of these warranties are available on request. MAINTENANCE. All Fensys products are designed to require very little maintenance; Fensys polymer products can be cleaned with lightly soaped water and the occasional jet wash. Fensys polymer products do not need painting, sanding or sealing. RECYCLING. Many of our products include a recycled element. Using polymer skinning technology, products can contain up to 80% recycled material sourced from industrial processing and products such as double glazed windows that have reached end of life. We also recycle 100% of our own process waste through utilisation of our in house recycling plant. All Fensys 100% polymer products are design to last and are 100% recyclable. FIRE SAFETY. Fensys premium boards have been tested according to BS EN ISO 11925-2:2010 Reaction to fire test for building products by accredited testers BTTG Technologies. Fensys polymer has been tested by Fire Technology Services (a UKAS accredited company) in accordance with BS 476: Part 7: 1987 (Method for classification of the surface spread of flame of products). Our material, specifically rigid PVC exceeded and was certified to the requirements of BS 476: Part 7: 1987 (as amended) Class 1. SLIP RESISTANCE. Fensys deck boards have been tested by independent slip risk assessors Grip Potential Limited. Both 100% polymer and 60/40 composite products have been tested in dry and wet conditions to BS7976-2. FENSYS GALVANISED SUB-FRAME STRUCTURAL CALCULATIONS. Independent structural calculations profiled by Hancock Wheedon & Ascough. Sub-frame calculations tested for maximum permissible deflection based upon a live uniformly distributed load of 1.5 KN/m2 or concentrated load of 1.4KN and a safety factor of x 1.5 PHYSICAL TESTING. Sub-frame physical testing carried out by Lloyds British Testing Limited. Sub-frame and deck boards tested to 1.5 KN/M2 and onto maximum permissible deflection based upon span/360. Product reached maximum permissible deflection of span/360 at 2.1 KN/M2 including a safety factor of x 1.5. Ultimate load failure recorded at 20 KN/M2. GALVANISED AND ZINC PLATED COMPONENTS. Cold rolled steel main frame profiles galvanised to British Standard BS EN 10346 : 2009. Sub-frame brackets are zinc plated and clear passivated to Fe/Zn25/A. BALUSTRADE HAND RAIL. Fensys balustrade system tested to the requirements of BS 6180 by independent accredited testers Lloyds British Testing Limited. Testing carried out to confirm that the Fensys rail, bracket and post system achieved or exceeded the minimum requirements as set out in BS6180. Horizontal uniformly distributed live load of 0.74 N/M2. Uniformly distributed load to infill’s of 1.0 KN/M2. Point load to centre of the infill’s of 0.5 KN. Minimum concentrated vertical load of 1 KN or uniformly distributed load of 0.6KN. Hand rail and post reinforcements are produced from cold rolled mild steel and are galvanised to British Standard BS EN 10346 : 2009. Copies of test certificates, structural calculations and or certificates of conformity are available on request. CARE POINTS. Fensys use the most suitable weather resistant materials for all components however there are a few product care points and things to watch out for. Consideration should always be given to who will be using the deck, especially for young children and animals. On hot days we recommend testing any surface with the back of your hand before use; worth noting lighter boards reflect more heat and so should be a consideration when choosing colour. Rubber mats are often manufactured from low grade materials that can damage/fade polymer deckboards. Avoid rubber mats and watch out for other rubber products such as furniture feet which can also react with the deckboards. Deckboards and hand railing can be damaged by chemical cleaners, some very basic house hold cleaners can attack and damage polymer; Fensys only recommend lightly soaped water. With 1000’s of cleaning, care and restoration products on the market, Fensys recommend contacting individual product manufacturers for advice on their suitability with Fensys materials. High temperature cleaning apparatus should not be used however with care, pressure washers can be used on Fensys materials. Sun cream can contain chemicals that react with and fade polymer, take special care when applying sun cream, allow it to thoroughly soak in before making contact with any Fensys product especially foiled hand rails. Ask for advice from your installer if your installation is in a salt spray zone/close to the sea; salt can greatly reduce the life of some materials especially those made from steel. Care should be taken to lift and place anything you are moving over the deck surface, dragging furniture/pots can damage your Fensys deckboard. Fensys materials include zinc plated components, Renolit foiled balustrade, UPVC skinned balustrade, UPVC skinned deckboards, ASA skinned deckboards. STATIC SHOCKS. Static induction sometimes experienced as a static shock is something that naturally occurs between a positively charged surface and negatively charged surface. Human skin especially dry skin has a tendency to build up a positively charged surface (especial on dry days when moisture in the atmosphere does not naturally dissipate charge) whilst some materials such as PVC have a tendency to have a negatively charged surface. These shocks are harmless but can be unpleasant, actions such as regular personal earthing, clothing choice, skin creams or hosing down your deck can help to minimise the risk but unfortunately for those prone to static shocks they are impossible to completely avoid. You can research the triboelectric series for a list of materials that cause static electricity. Should you need any further information Contact our team for advice |

Premium Eco Beige Deckboard  Premium Excel Antique Oak Deckboard  Premium 100% Polymer Composite Deckboard  Premium Excel Natural Effect deckboard  Premium Excel Natural Effect Deckboard  Foiled wood grain Georgian handrail  Double glazed windows for recycling  Decking galvanised steel sub-frame  Fensys load testing |

- Fensys

- Fensys about us

- Fensys Quotation

- Fensys Installation

- Fensys News

- Testimonial Beaumont

- Testimonial Cosgrove

- Testimonial Drayton

- Tips on Sundeck Design

- Style Board – The Optimal Decking board

- Style Board – Installed with a curve

- Style Board – Home Garden Installation

- Premium Eco & Excel Deck Boards

- Fensys Media Hub

- Fensys – Frequently asked questions

- Literature Download

- Products

- Information Decking & Skirting

- Information UPVC Fencing

- Information UPVC Gates

- Technical Information Decking

- Technical Information Fencing

- Technical Information Gates

- Gallery Holiday Home Decking

- Gallery Caravan Deck Designs

- Gallery Home Garden & Composite Decking

- Gallery Commercial Decking Areas

- Gallery UPVC Skirting

- Gallery UPVC Fencing

- Gallery UPVC Gates

- Gallery Fensys Components

- Contact us

- PAL Group